How to Balloon a Part Drawing For Inspection Using a PDF Editor

Learn everything you need to know about ballooning PDF drawings for inspection documentation.

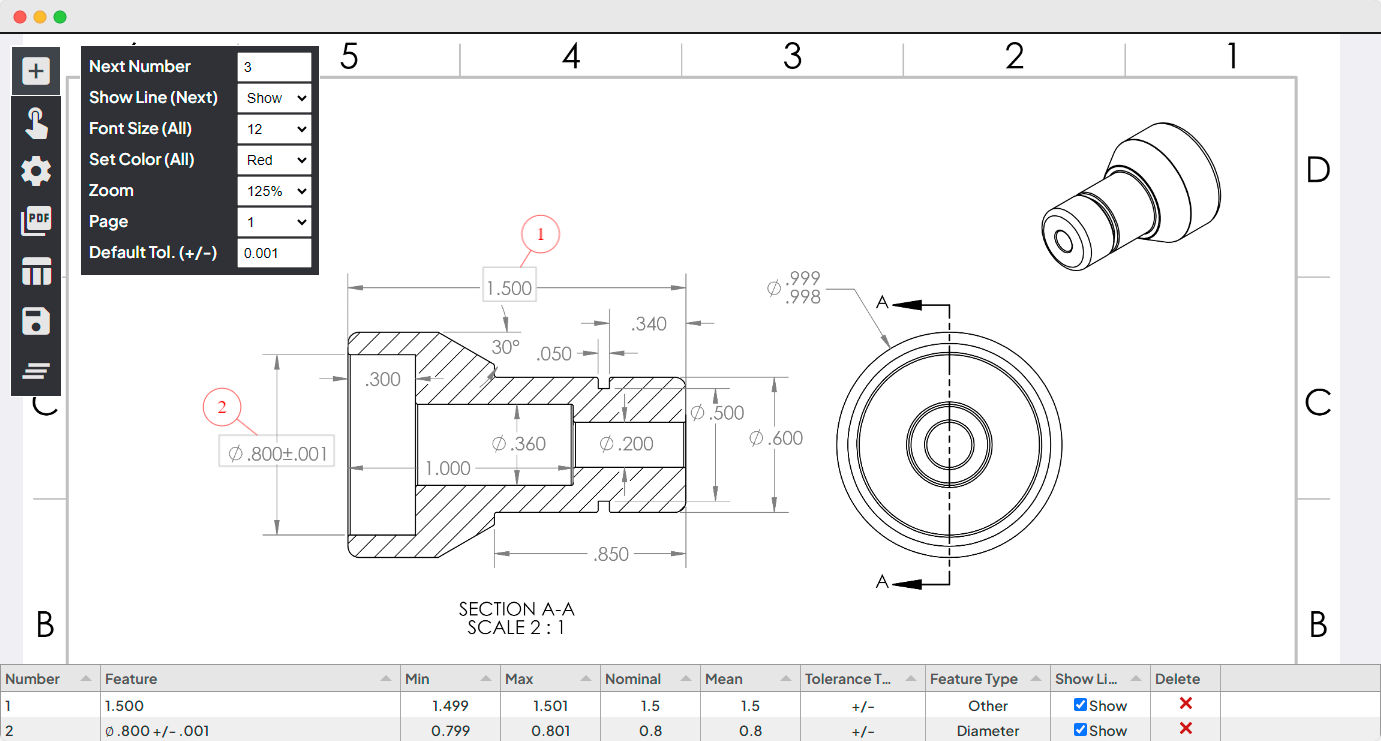

Example of PDF ballooning using Balloonist.io

As a quality manager, you're no stranger to the task of ballooning inspection drawings. This critical process ensures that every feature on a part is accounted for and inspected according to specifications. However, if you’re using a standard PDF editor, you’ve likely experienced just how tedious and time-consuming this task can be.

The Workflow

Let’s break down the typical process. You start with a PDF of the inspection drawing. The goal is to identify each feature—be it a hole, surface, or dimension—that requires inspection and assign it a unique number, typically encircled for easy identification. This process, known as "ballooning," is straightforward in theory but becomes laborious in practice.

Using a PDF editor, you’ll likely rely on the annotation tool to draw a circle around each feature. Next, you manually type in a number next to each circle, incrementing by one with each new feature. This might sound simple enough, but when you're dealing with a drawing that has dozens or even hundreds of features, the process quickly becomes a chore.

This can become a tedious process:

- Manual Numbering: Each number must be manually typed in, making it easy to misnumber a feature or duplicate a number. This step requires constant attention to detail to ensure every feature is uniquely identified, and any mistake could lead to confusion during the inspection process.

- Revisions: If a drawing is revised and new features are added, you’re faced with the task of renumbering existing features or squeezing in new numbers where there’s already limited space. This can lead to inconsistent numbering, cluttered drawings, and increased chances of error.

- Repetitive Actions: You’re repeating the same few actions—drawing a circle, typing a number—over and over again. For a drawing with many features, this repetitive task becomes monotonous and mentally draining.

- Error-Prone Process: The manual nature of this process leaves ample room for human error. A slight misstep could mean overlooking a feature or misnumbering, leading to potential delays and costly mistakes in the inspection process.

The Impact on Quality Management

Ballooning inspection drawings is not just a tedious task — it has real implications for quality management. If a feature is incorrectly numbered or missed altogether, it could result in an incomplete or inaccurate inspection, leading to defects slipping through the cracks. This, in turn, can affect product quality, customer satisfaction, and ultimately, the reputation of your company.

Moreover, the time spent on ballooning could be better used elsewhere. As a quality manager, your expertise is valuable, and tasks like ballooning are not the best use of your time. The repetitive nature of this task could lead to burnout and reduce your overall efficiency.

Other Solutions

Given the importance of accurate inspection and the tedious nature of manual ballooning, it’s worth exploring tools designed to streamline this process. Specialized software can automate the numbering process, reduce errors, and significantly cut down the time required to prepare inspection drawings. Investing in such tools can enhance the accuracy and efficiency of your inspection processes, ultimately leading to better quality management and higher customer satisfaction.

While ballooning inspection drawings using a PDF editor is a critical part of quality management, it’s also a task fraught with potential for error and inefficiency. By acknowledging the limitations of this manual process, you can start exploring more efficient solutions that allow you to focus on what really matters—ensuring the highest quality standards for your products.

Ready to streamline your inspection process?

Try Balloonist.io today & reduce the time it takes to balloon drawings and create FAI Reports

Start Free Trial